Recent Blog

-

What are the limitations of traditional wheel alignment methods?

2024-05-16 -

Is wheel alignment the same as balancing?

2024-05-16 -

How do 3D wheel alignment systems contribute to efficiency and speed in automotive workshops?

2024-05-16 -

Can I use a tool trolley for purposes other than auto repair?

2024-05-07

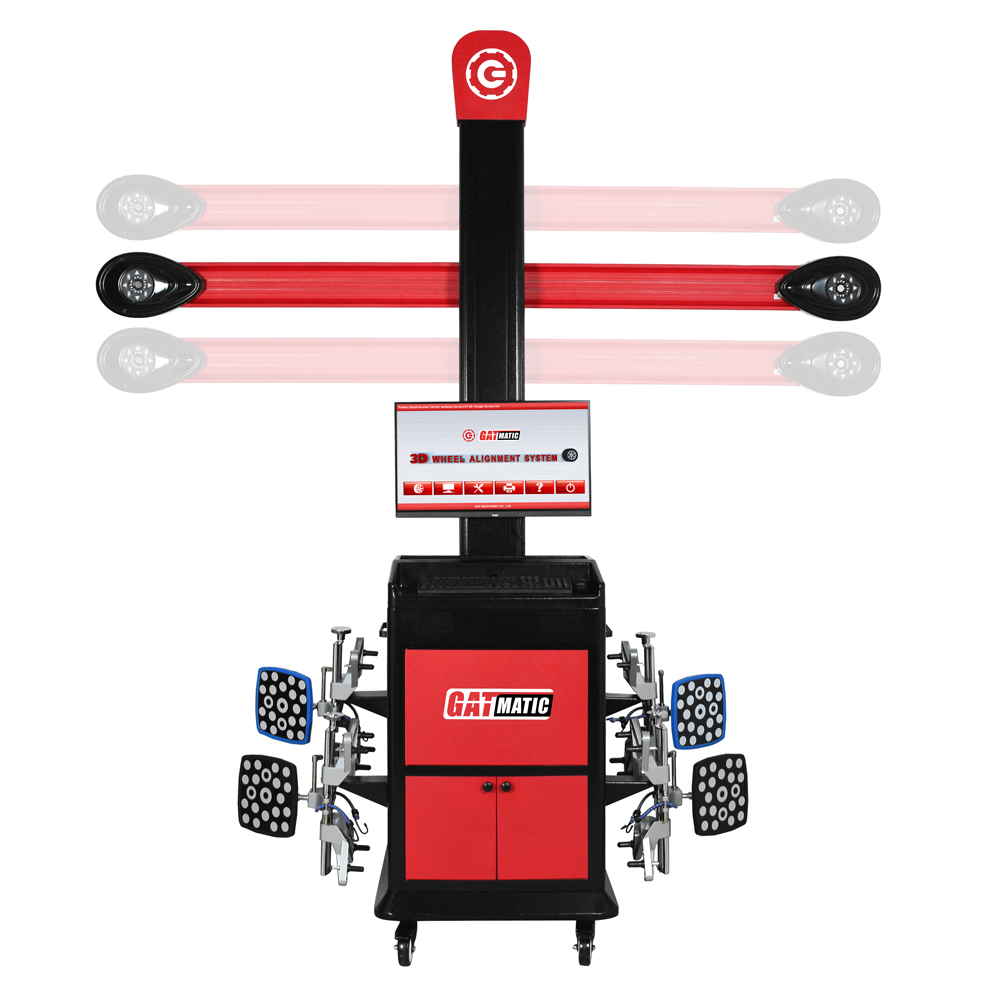

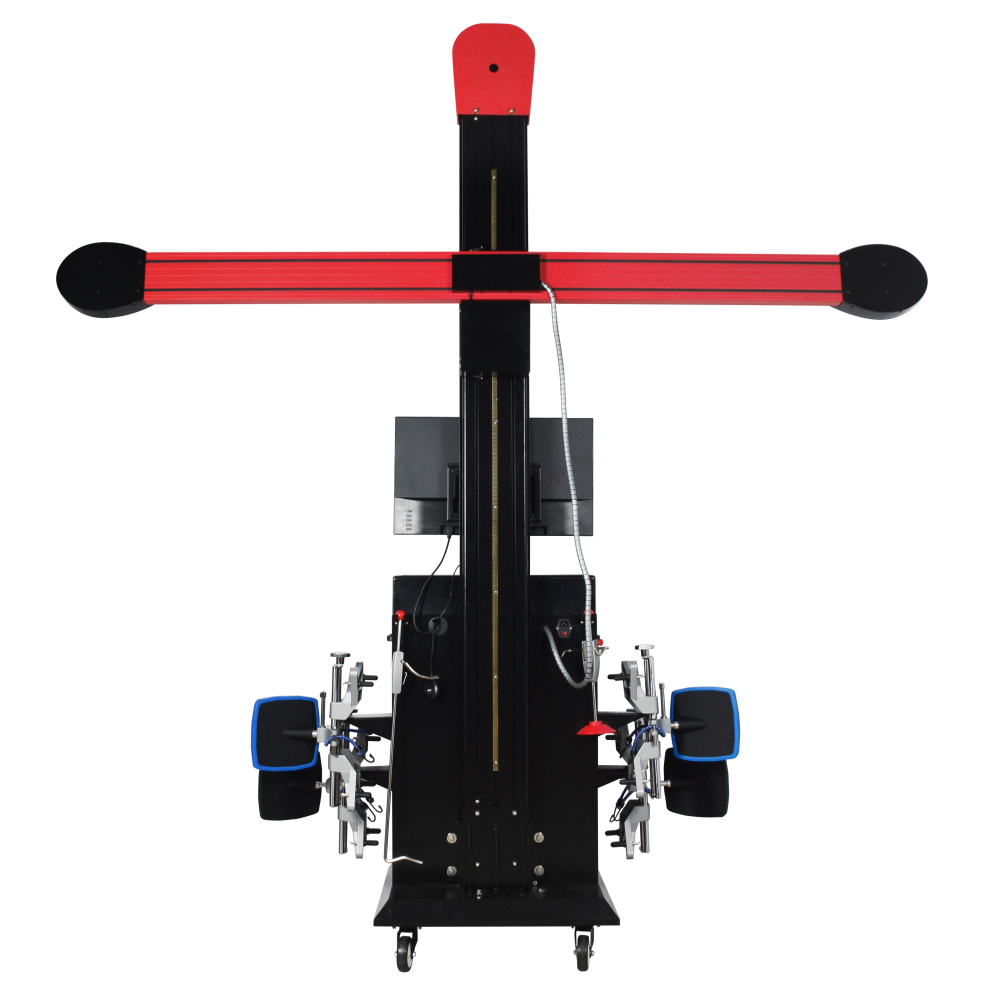

Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine How to ensure security and stability

The Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine represents a remarkable advancement in automotive technology, enabling precise wheel alignment with unprecedented ease and accuracy. As automotive equipment becomes more sophisticated, the need to ensure its security and stability becomes paramount. This essay explores the measures required to guarantee the safety, integrity, and reliable performance of the Gat-matic Auto Tracking machine.

I. Security Measures

- The physical security of the Gat-matic system is the first line of defense. Controlled access to the machine’s location and the installation of surveillance cameras ensure that only authorized personnel can interact with the equipment. This prevents tampering or unauthorized usage. Furthermore, implementing secure storage for sensitive components adds an extra layer of protection against theft or vandalism.

- Authentication and authorization mechanisms are essential to regulate user access. Multi-level authentication processes ensure that only authorized individuals can operate the machine. Role-based permissions limit user privileges, preventing unauthorized modifications or access to critical settings. This approach safeguards against accidental or intentional misuse.

- Data security is equally crucial. Encrypting data transmission and storage prevents unauthorized interception or access to sensitive information. Regular data backups and secure off-site storage provide redundancy in case of data loss, ensuring the integrity of historical alignment records. Additionally, protecting against unauthorized data retrieval safeguards valuable customer and proprietary data.

II. Stability Enhancements

- Quality manufacturing is fundamental for stability. The Gat-matic machine must be built using high-quality materials to withstand the rigors of daily use. Stringent quality control during the manufacturing process ensures that each unit meets the highest standards, reducing the likelihood of defects that could compromise stability.

- Robust mechanical design plays a pivotal role in the longevity and stability of the equipment. Anti-vibration mechanisms prevent external vibrations from affecting alignment accuracy. The reinforced chassis and components are engineered to withstand mechanical stress, maintaining the machine’s precision and stability even in demanding conditions.

- Precision calibration is essential for accurate wheel alignment. Regular calibration checks are imperative to ensure that the machine consistently provides reliable measurements. Implementing self-calibration routines further enhances stability, as the machine can autonomously correct minor deviations, reducing the need for manual intervention.

- Environmental considerations are often overlooked but crucial for sustained stability. Adequate ventilation prevents overheating, which can impact both the hardware and software components. Protection against dust, moisture, and other environmental factors ensures that the machine operates optimally regardless of the surroundings.

III. Software Security

- Secure software development is pivotal in today’s interconnected world. Following best practices in software development and coding minimizes vulnerabilities that could be exploited by malicious actors. Regular software updates are essential to patch any potential security holes that are discovered.

- Effective malware prevention mechanisms must be in place to counter potential threats. Employing reputable antivirus and anti-malware software safeguards against known threats. Network security measures, such as firewalls and intrusion detection systems, prevent malware from infiltrating the machine through network connections.

- Remote access controls are particularly important for maintenance and support. While remote assistance can expedite issue resolution, it also presents security risks. Secure remote access protocols and two-factor authentication ensure that only authorized personnel can remotely access the machine’s systems, reducing the risk of unauthorized access or control.

IV. Maintenance and Training

- Routine maintenance is key to preserving stability. Scheduled inspections and maintenance checks identify potential issues before they escalate, minimizing downtime and preventing stability-related problems. Prompt repair of any identified issues is essential to prevent minor problems from developing into major disruptions.

- Comprehensive user training is vital to ensure proper operation and security practices. Operators and technicians must be educated on how to use the machine correctly and follow security protocols. This human element is often a weak point in security and stability, making training an integral part of the overall strategy.

v. Compliance and Regulations

- Adherence to industry standards is crucial for ensuring the security and stability of automotive equipment. Gat-matic Auto Tracking should conform to relevant automotive and equipment standards to ensure interoperability and safety. Seeking certifications from recognized bodies further validates compliance and reliability.

- Data privacy regulations, such as GDPR or HIPAA, must be adhered to, particularly when handling customer data. Implementing transparent data usage policies and obtaining user consent for data collection and storage builds trust and ensures compliance with legal requirements, enhancing both security and stability.

IV. Continuous Improvement

- Feedback mechanisms are invaluable for identifying potential security or stability issues. Gathering feedback from users and technicians who interact with the machine on a daily basis can help identify areas for improvement. Incorporating feedback-driven improvements enhances both user experience and overall performance.

- Investing in research and development is a long-term strategy for maintaining security and stability. As new security technologies emerge, Gat-matic should be at the forefront of adopting them. Continuous innovation not only enhances security but also opens avenues for improving the machine’s functionality and overall value proposition.

Conclusion

The Gat-matic Auto Tracking 3D Movable Wheel Alignment Machine represents a technological marvel that redefines automotive wheel alignment. However, without the proper security and stability measures in place, even the most advanced equipment can be rendered ineffective or compromised. By implementing robust security protocols, ensuring mechanical and environmental stability, and adhering to industry regulations, Gat-matic can deliver on its promise of precision and reliability, setting new standards for the automotive industry.

Describe Your Needs In Detail!

We will carefully evaluate your needs and give professional solutions.